Quality Standards and Specifications for Pastille Sulfur

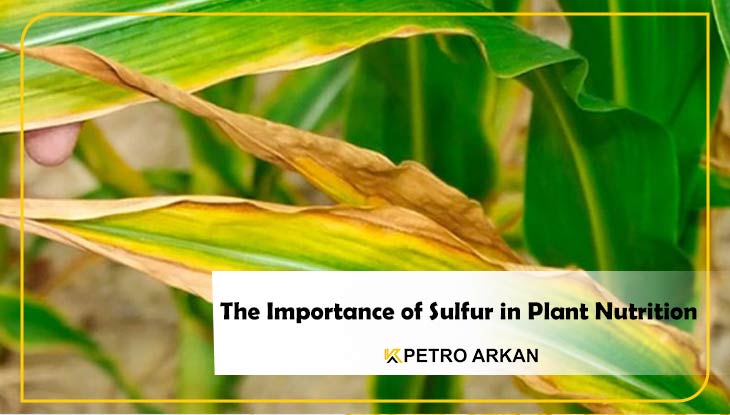

Quality Standards of Pastille Sulfur, a refined form of elemental sulfur shaped into small, is widely utilized across various industries, including agriculture, chemical manufacturing, and pharmaceuticals.

Ensuring the highest quality standards and specifications for pastille sulfur is crucial to its effectiveness and safety in these applications. Quality Standards of Pastille Sulfur encompass many great features which in this article we will talk about.

Pastille sulfur specifications

Quality Standards of Pastille Sulfur are defined to ensure its suitability for various industrial applications. Pastille sulfur, typically manufactured through a process of melting and solidification, undergoes stringent quality control measures to meet these specifications.

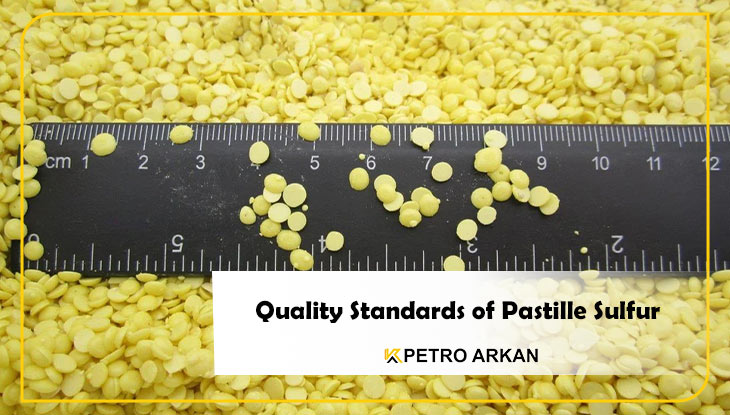

During production, molten sulfur is carefully processed to form uniform ones, ensuring consistency in size, shape, and purity. These pellets are then subjected to rigorous testing and analysis to verify adherence to quality standards, including purity levels exceeding 99.5% elemental sulfur content, minimal impurities such as ash and moisture, and consistent physical properties.

Through precise attention to detail and apply of stringent quality control protocols, Quality Standards of Pastille Sulfur maintains its reputation as a reliable and versatile material in industries ranging from agriculture to pharmaceuticals.

Key parameters include purity, size, shape, colour, and chemical composition. Here is a breakdown of the typical specification of Pastille Sulfur:

| Parameter | Specification |

| Purity (Sulfur Content) | ≥ 99.5% |

| Ash Content | ≤ 0.05% |

| Moisture Content | ≤ 0.5% |

| Acidity (as H2SO4) | ≤ 0.01% |

| Particle Size Distribution | 90% particles between 2 mm and 5 mm |

| Colour | Bright Yellow |

Standards for pastille sulfur quality

Quality Standards of Pastille Sulfur are important to ensure its efficacy and safety across diverse industrial applications. These standards encompass stringent requirements about purity, physical properties, and compliance with environmental and safety regulations.

Pastille Sulfur typically boasts a purity level exceeding 99.5% elemental sulfur content, with minimal impurities such as ash, moisture, and trace metals.

This high purity ensures optimal performance in processes such as sulfuric acid production, agricultural applications, and pharmaceutical manufacturing.

In addition to purity, standards for pastille sulfur quality also address physical properties such as particle size distribution, shape, and colour.

Pastille sulfur is produced in uniform pellet shapes and sizes, facilitating ease of handling, storage, and application in various industrial processes.

Bright yellow colouration is often indicative of high-quality sulfur, signifying its purity and lack of significant contaminants. A characteristic sulfur odour, slight, may be present in the Quality Standards of Pastille Sulfur, serving as a natural attribute of elemental sulfur.

Compliance with environmental and safety regulations is another integral aspect of pastille sulfur quality standards. Manufacturers apply strict guidelines to minimize environmental impact and ensure workplace safety throughout the production, handling, and transportation processes.

Certifications and documentation, including Certificates of Analysis (COAs) and Material Safety Data Sheets (MSDS), assure that pastille sulfur meets regulatory requirements and industry standards.

By upholding the Pastille Sulfur, pastille sulfur remains a trusted and reliable material in various industrial sectors, supporting sustainable and safe practices in its use.

Pastille sulfur certification requirements

Quality Standards of Pastille Sulfur are vital to guarantee its quality, safety, and suitability for use across diverse industrial applications.

These certification processes encompass thorough evaluations of various parameters, including purity, physical characteristics, environmental compliance, and documentation.

Purity is a primary focus, with high-grade pastille sulfur typically requiring a sulfur content of at least 99.5%, accompanied by minimal impurities such as ash, moisture, and trace metals.

Certified laboratories conduct detailed analyses using advanced techniques like X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectroscopy to ensure accurate measurement of sulfur content and impurities.

Physical characteristics such as particle size distribution, shape, and colour, are also evaluated during certification. Quality Standards of Pastille Sulfur is expected to exhibit uniform pellet shapes and sizes, typically ranging from a few millimetres to centimetres in diameter.

Consistent particle size distribution ensures ease of handling and application in various industrial processes. Moreover, pastille sulfur with a bright yellow colouration is indicative of high purity and minimal contamination, while a characteristic sulfur odour, albeit slight, may be present as a natural attribute of elemental sulfur.

Environmental and safety compliance is paramount in pastille sulfur certification. Manufacturers must adhere to stringent regulations to minimize environmental impact and ensure workplace safety throughout the production, handling, and transportation processes.

Compliance with regulations regarding emissions control, waste management, and worker safety is thoroughly assessed to mitigate risks and uphold sustainability standards.

Comprehensive documentation is required to verify compliance with regulatory requirements and industry Quality Standards of Pastille Sulfur.

Certificates of Analysis (COAs), Material Safety Data Sheets (MSDS), and compliance declarations assure pastille sulfur’s quality, safety, and regulatory compliance throughout its lifecycle.

Quality Standards of Pastille Sulfur ensures that the product meets the highest quality standards and regulatory requirements for its intended applications.

By adhering to these rigorous certification processes, manufacturers can provide customers with confidence in the reliability, safety, and performance of pastille sulfur in various industrial sectors, including agriculture, chemical manufacturing, and pharmaceuticals.

Getting Pastille Sulfur?

When it comes to acquiring pastille sulfur for your industrial needs, ensuring quality and reliability is paramount. Look no further than trusted suppliers who prioritize stringent Quality Standards of Pastille Sulfur measures and adhere to industry standards.

Pastille sulfur, renowned for its versatility in applications ranging from agriculture to chemical manufacturing, demands the highest standards to guarantee optimal performance and safety.

Make the smart choice today and secure your supply of pastille sulfur from trusted sources for peace of mind in your industrial processes.

Their comprehensive quality control processes, coupled with thorough documentation and certification, provide customers with the assurance of receiving premium products.

Petro Arkan’s dedication to sustainability and safety further solidifies its reputation as a trusted and responsible provider of Pastille Sulfur, supporting the diverse needs of industries worldwide.

Summation

Quality Standards of Pastille Sulfur are defined to ensure its efficacy and safety. Manufacturers apply to meet enough certification requirements, conducting thorough evaluations of purity. Ensure that pastille sulfur meets the highest quality standards and regulatory requirements.

Through these things to these rigorous standards, the Quality Standards of Pastille Sulfur remains a trusted and reliable material supporting sustainable and safe practices across diverse industrial sectors.

FAQ Questions:

- What is the typical purity requirement for pastille sulfur?

Pastille sulfur typically requires a purity of ≥ 99.5% elemental sulfur content.

- What are the key physical characteristics evaluated in pastille sulfur?

Physical characteristics include particle size distribution, shape, colour (bright yellow), and odour (slight sulfur odour).

- How is environmental compliance ensured in pastille sulfur production?

Manufacturers adhere to stringent regulations regarding emissions control, waste management, and worker safety to ensure environmental compliance.

Category:

| Urea |

| Granular |

| prill |

| technical |

| Sulfur |

| Granular |

| lump |

| pastille |

| Soda ash |

| light |

| dense |

| Castic soda |

| flake |

| liquid |

| AMMONIUM CHLORIDE |

| Sodium sulfide |

Other post:

Complete specifications of Lump Sulfur – Benefits and Applications

Detailed guide to technical urea – more than 4 fields to apply

No comment