Quality Standards and Specifications for Granular Sulfur

Quality Standards of Granular Sulfur play a crucial role in ensuring the reliability, safety, and effectiveness of products across various industries.

In the case of granular sulfur, these standards are paramount due to their widespread use in diverse applications ranging from agriculture to industrial processes.

Quality Standards of Granular Sulfur, a vital component in fertilizer production, chemical synthesis, and pest control, must meet stringent criteria to guarantee its performance and compatibility with specific applications.

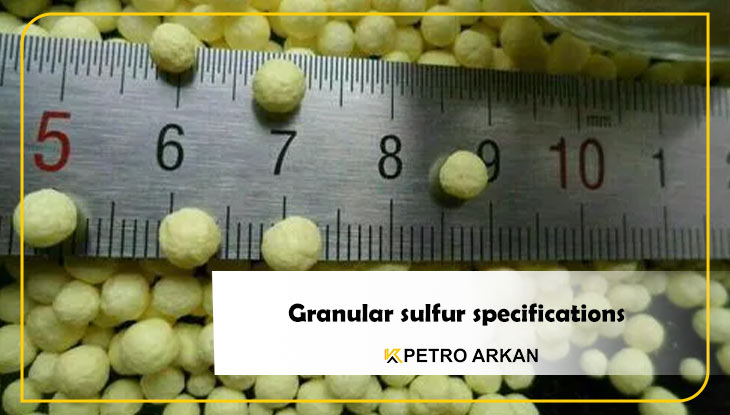

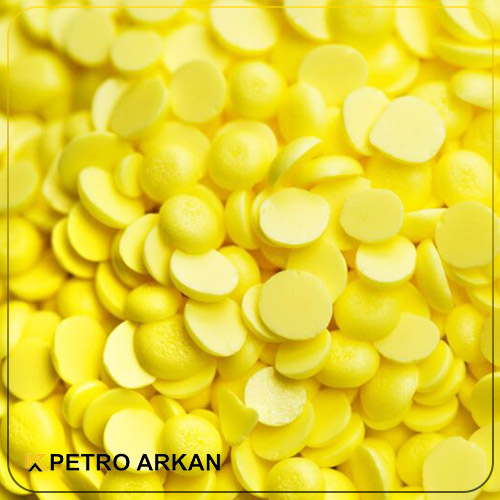

Granular sulfur specifications

Quality Standards of Granular Sulfur are subject to rigorous specifications to ensure its suitability for various industrial and agricultural applications. These specifications encompass key parameters including purity, particle size distribution, moisture content, and elemental composition:

- Purity: Granular sulfur must have a minimum purity of 99.5%, ensuring that impurities are kept to a minimum to maintain its efficacy in intended applications.

- Particle Size Distribution: The granular sulfur should have a particle size ranging from 2 to 6 mm, with at least 90% of particles falling within this range. This ensures uniformity and ease of handling during application.

- Moisture Content: The moisture content of granular sulfur must not exceed 0.5%, preventing issues such as caking and ensuring its stability during storage and transportation.

- Ash Content: The ash content should be kept below 0.3% to minimize residues and impurities that may affect product performance.

- Colour and Odor: Granular sulfur should exhibit a bright yellow colour and be odourless, indicating its purity and quality.

- Elemental Composition: The sulfur product should have low levels of sulfate and heavy metal contaminants such as iron, copper, zinc, arsenic, lead, and mercury, ensuring its environmental safety and compatibility with intended applications.

- Packaging: Granular sulfur is typically packaged in 25 kg bags or available in bulk, ensuring convenient handling and storage for end-users.

Adherence to these specifications ensures that Quality Standards of Granular Sulfur meets the highest quality standards, enabling its effective use in diverse industrial and agricultural processes.

| Parameter | Specification |

| Purity | ≥ 99.5% |

| Particle Size Distribution | 2 – 6 mm (90% min) |

| Moisture Content | ≤ 0.5% |

| Ash Content | ≤ 0.3% |

| Colour | Bright Yellow |

| Odor | Odorless |

| Sulfate Content | ≤ 0.2% |

| Iron Content | ≤ 100 ppm |

| Copper Content | ≤ 10 ppm |

| Zinc Content | ≤ 10 ppm |

| Arsenic Content | ≤ 3 ppm |

| Lead Content | ≤ 3 ppm |

| Mercury Content | ≤ 0.1 ppm |

| Packaging | 25 kg bags, bulk |

Standards for granular sulfur quality

Quality Standards of Granular Sulfur are vital to ensure its efficacy, safety, and suitability for various industrial and agricultural applications.

These standards encompass a range of parameters, including purity, particle size distribution, moisture content, and elemental composition.

Quality Standards of Granular Sulfur To establish standards, manufacturers can guarantee that their granular sulfur products meet the required quality benchmarks, facilitating trust among consumers and regulatory compliance.

Purity is a critical aspect of granular sulfur quality standards, with minimum purity levels typically set at 99.5% or higher.

This ensures that the sulfur product is free from impurities that could compromise its effectiveness in applications such as fertilizer production, chemical synthesis, and pest control.

Additionally, strict limits on moisture content prevent issues such as caking and degradation during storage and transportation, ensuring the product’s stability and longevity.

In addition to purity and moisture content, Quality Standards of Granular Sulfur also address factors such as particle size distribution and elemental composition.

Particle size distribution is crucial for ensuring uniformity and ease of handling, while limits on elemental contaminants such as heavy metals ensure environmental safety and compatibility with intended applications.

Overall, Quality Standards of Granular Sulfur are essential for maintaining the integrity and reliability of granular sulfur products, enabling their successful utilization across diverse industries.

Granular sulfur certification requirements

Certification requirements for Quality Standards of Granular Sulfur are typically intended to ensure that the product meets specific safety and quality standards set by a regulatory agency or industry organization.

These requirements may vary depending on the intended use of the sulfur and the regulations in the area where the sulfur is produced or sold.

Compliance with Quality Standards of Granular Sulfur, such as purity levels, particle size distribution, and elemental composition, is crucial to meet the needs of various industrial and agricultural applications.

Safety and environmental regulations also play a significant role, with limits on contaminants and guidelines for safe handling, storage, and disposal ensuring protection for both human health and the environment.

Moreover, the Quality Standards of Granular Sulfur, tailored to the unique requirements of sectors like agriculture or chemical processing, further reinforce the product’s quality and suitability.

By obtaining certification, manufacturers demonstrate their commitment to meeting these standards, enhancing consumer confidence and facilitating trade in the global market

This often involves testing product samples against specific criteria to ensure consistency and reliability. Safety and environmental regulations, Quality Standards of Granular Sulfur certification may also involve compliance with safety and environmental regulations that protect human health and the environment.

This may include limits on the presence of contaminants such as heavy metals and following instructions for safe handling, storage and disposal of the product. Specific industry standards, Depending on the industrial application of granular sulfur, specific industry standards or certifications may be required.

For example, sulfur used in agriculture as a fertilizer may need to meet standards set by agricultural regulators, while sulfur used in chemical processes may need to comply with standards set by relevant agrochemical associations.

Labeling and Documentation, Certification requirements typically include provisions for accurate labeling and documentation of the product, including ingredient information, safety precautions, and handling instructions.

This helps ensure that users have access to important information needed to use the product safely and effectively. Audits and Inspections, Certification bodies may conduct audits or inspections of manufacturing facilities to verify compliance with certification requirements.

This may involve reviewing manufacturing processes, quality control measures and documentation to ensure all requirements are consistently met.

By achieving certification for Quality Standards of Granular Sulfur products, manufacturers can demonstrate their commitment to quality, safety and regulatory compliance, building trust with customers and other stakeholders.

Buying the best quality of Granular Sulfur

When purchasing granular sulfur, ensuring the highest quality is paramount to achieving desired results in various industrial and agricultural applications. Petro Arkan, renowned for its commitment to excellence in the petrochemical industry, stands out as a reliable source of Quality Standards for Granular Sulfur.

With a reputation built on stringent quality control measures and adherence to industry standards, Petro Arkan’s granular sulfur products boast exceptional purity, precise particle size distribution, and minimal contaminants, ensuring optimal performance and compatibility with diverse applications. By choosing Petro Arkan, buyers can confidently invest in granular sulfur of the highest calibre, backed by a trusted brand synonymous with quality and reliability.

Summation

Quality Standards of Granular Sulfur are critical in ensuring the efficacy, safety, and applicability of granular sulfur across diverse industrial and agricultural sectors.

Maintaining compliance with these standards guarantees the product’s performance integrity, environmental safety, and suitability for various applications.

Certification requirements further validate adherence to these standards, ensuring that granular sulfur meets stringent quality benchmarks and regulatory guidelines.

This involves rigorous testing, documentation, and possibly audits of manufacturing processes to verify consistent Quality Standards of Granular Sulfur with safety protocols, thereby bolstering consumer confidence and facilitating market access for manufacturers.

FAQ Questions

- What are the key parameters to consider when buying granular sulfur?

Purity, particle size distribution, and elemental content.

- Why is granular sulfur certification important?

Ensures quality, safety, and compliance with standards.

- How can I ensure the quality of granular sulfur for my specific application?

Check specifications and certifications.

Category:

| Urea |

| Granular |

| prill |

| technical |

| Sulfur |

| Granular |

| lump |

| pastille |

| Soda ash |

| light |

| dense |

| Castic soda |

| flake |

| liquid |

| AMMONIUM CHLORIDE |

| Sodium sulfide |

Other Post:

Quality Standards of Pastille Sulfur – Certification requirements

No comment