Granular Sulfur vs. Powdered Sulfur, is an essential nutrient in agriculture and plays a vital role in plant growth, soil health, and disease control.

Both materials serve important functions but differ significantly in their physical properties, application methods, and specific benefits.

Understanding these differences is important for farmers to make informed decisions about the appropriate type of sulfur based on their specific agricultural needs. For getting more information about Granular Sulfur vs. Powdered Sulfur be with Us.

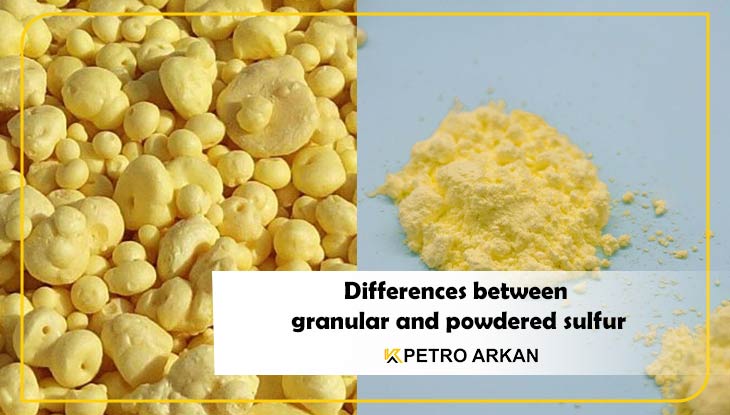

Differences between granular and powdered sulfur

Granular Sulfur vs. Powdered Sulfur have some differences from each other. You can see these differences here:

| Aspect | Granular Sulfur | Powdered Sulfur |

| Physical Form | large, granular particles | Small, powdery particles |

| Application Method | Typically applied directly to soil; easier to handle | Often requires mixing with water or other agents; more difficult to handle |

| Dissolution Rate | Slow-release; gradually dissolves and integrates into the soil | Fast-release; quickly available to plants and soil |

| Handling and Storage | Less liable to dust formation; easier to store and transport | Can create dust; requires careful handling and storage |

| Effectiveness | Provides a steady, long-term supply of sulfur | Offers immediate sulfur availability for quick results |

| Use Cases | Ideal for long-term soil amendment and pH adjustment | Suitable for quick correction of sulfur deficiencies and immediate soil treatment |

| Cost | Generally, more cost-effective due to the ease of application | May be more expensive due to higher processing costs |

Granular vs. powdered sulfur

Granular Sulfur vs. Powdered Sulfur is formed by-product of gas processing, especially the gas sweetening process to remove H2S. Then converted to liquid sulfur in a sulfur recovery unit (SRU) which is finally processed into granular sulfur.

Granular Sulfur

Granular sulfur, as the name suggests, is formed by the slow accumulation of successive layers of sulfur around a central core. This allows the size of the final product to be controlled.

Sulfur granulation is a size increase process. Small sulfur particles (particles below the size of) are repeatedly sprayed with liquid sulfur and allowed to cool. Repeated applications of liquid sulfur cause the particle to increase in volume and weight.

The particle is covered until it reaches a 2-6 mm diameter. As the particle grows, each coat of liquid sulfur completely and structurally bonds with the layer below. This produces spherical particles that dry completely and are free of voids.

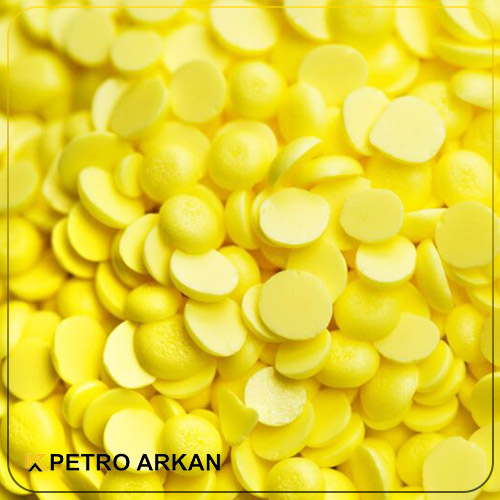

Sulfur pasting uses a liquid sulfur injector to drip liquid sulfur onto a steel belt cooler in a regular line. As the liquid sulfur travels over the steel belt cooler it loses heat and forms uniform hemispheres called lozenges.

The production of sulfur lozenges is an increasingly popular method of producing solid sulfur due to the relative ease of setup and the high quality of the final product.

Sulfur Powder

Sulfur powder is produced in a variety of standard particle sizes from -40 to -350 mesh and sub-micron. The process of producing finely divided sulfur powder is hazardous and energy-inefficient.

Sulfur powder is often used in agricultural insecticides and fungicides, either in the form of dust or as wettable sulfur in spray mixtures with other pesticides.

Sulfur powder is also used in the manufacture of fertilizers, vulcanization of rubber, pharmaceuticals, explosives, and in the manufacture of other chemicals.

The ignition temperature of sulfur powder is about 190 °C, and dust clouds produced by handling sulfur pose an explosion hazard.

Static electricity on the particles can irritate them. Must be stored in a well-ventilated area to reduce the risk of fire or explosion.

Advantages of granular sulfur over powdered sulfur

Granular Sulfur vs. Powdered Sulfur in various applications, particularly in agriculture and industrial uses. Here are the main advantages of Granular Sulfur vs. Powdered Sulfur:

1. Dust Control and Safety

- Reduced Dust, Granular sulfur produces less dust compared to powdered sulfur. This makes it safer to handle and reduces the risk of dust-related health issues and explosions.

- Improved Safety, the reduced dust also lowers the risk of inhalation and associated respiratory problems for workers handling sulfur.

2. Ease of Handling and Storage

- Better Flowability, Granular sulfur flows more easily than powdered sulfur, making it simpler to handle, transport, and apply using standard agricultural equipment.

- Less Caking, Granular sulfur is less prone to caking and clumping, which makes storage and handling more convenient.

3. Application Efficiency

- Uniform Distribution, Granules can be spread more evenly over a larger area, ensuring a more consistent application. This is particularly important in agricultural settings where uniform distribution affects crop yields.

- Controlled Release, Granular sulfur can provide a slower, more controlled release of sulfur into the soil, improving nutrient availability to plants over time.

4. Environmental Impact

- Reduced Runoff, Granular sulfur is less likely to be carried away by wind or water, reducing environmental contamination and ensuring more of the sulfur reaches its intended destination.

- Lower Volatility, Granules are less volatile compared to powder, which can reduce losses due to evaporation or wind dispersion.

5. Economic Considerations

- Reduced Waste, The reduced dust and better application efficiency of granular sulfur led to less waste, potentially lowering overall costs.

- Improved Effectiveness, More consistent and controlled applications can improve the effectiveness of sulfur as a soil amendment or industrial input, enhancing the cost-effectiveness of its use.

6. Mixing and Blending

- Compatibility with Other Fertilizers, Granular sulfur can be easily blended with other granular fertilizers, allowing for customized fertilizer mixes tailored to specific soil or crop needs.

7. Longer Shelf Life

- Stability, Granular sulfur typically has a longer shelf life compared to powdered sulfur, maintaining its effectiveness over extended periods without significant degradation.

These advantages make granular sulfur a preferred choice for many agricultural and industrial applications, offering improved safety, efficiency, and cost-effectiveness.

Where to buy powder Sulfur?

For those seeking high-quality powdered sulfur, look no further than Petro Arkan, a leading supplier renowned for its exceptional products and reliable service.

Whether you’re in agriculture, pharmaceuticals, or any other industry requiring premium sulfur, Petro Arkan will support you.

With a commitment to purity and performance, Granular Sulfur vs. Powdered Sulfur. Visit Petro Arkan’s website today to explore their extensive range of sulfur products and place your order with confidence, knowing you’re choosing a trusted name in the market.

Summation

Choosing between Granular Sulfur vs. Powdered Sulfur for your farm involves understanding their distinct properties and specific benefits.

Granular sulfur, formed through processes like drum granulation, offers advantages such as reduced dust and environmental benefits like reduced runoff and lower volatility.

Granular Sulfur vs. Powdered Sulfur makes it ideal for long-term soil amendment and pH adjustment.

On the other hand, powdered sulfur, often produced through mechanical grinding, provides fast-release sulfur, making it suitable for quick correction of deficiencies and immediate soil treatment.

FAQ Questions

- What are the main differences between granular and powdered sulfur in terms of application?

Granular sulfur is easier to handle and provides slow-release sulfur. Powdered sulfur offers immediate availability but requires careful handling due to dust.

- Which type of sulfur is more cost-effective for long-term soil amendment?

Granular sulfur is more cost-effective due to easier application and controlled release.

- How does the dust formation of granular sulfur compare to powdered sulfur?

Granular sulfur produces less dust, making it safer and easier to handle.

Category:

| Urea |

| Granular |

| prill |

| technical |

| Sulfur |

| Granular |

| lump |

| pastille |

| Soda ash |

| light |

| dense |

| Castic soda |

| flake |

| liquid |

| AMMONIUM CHLORIDE |

| Sodium sulfide |

Other posts:

The Importance of sulfur in plant nutrition + 9 benefits for plants

Quality Standards of Lump Sulfur – Criteria & specifications

No comment