Lump Sulfur vs. Granular Sulfur, a fundamental element in agriculture and industry, is available in various forms, with lump sulfur and granular sulfur being two commonly used types. While both serve similar purposes in providing essential sulfur to plants.

Understanding the distinctions between Lump Sulfur vs. Granular Sulfur is crucial for farmers and industrial users alike, as it enables them to make informed decisions regarding soil amendment, and crop health.

Differences between lump and granular sulfur

Lump Sulfur vs. Granular Sulfur, while both are valuable sources of sulfur for agricultural and industrial purposes existence several key differences between Lump Sulfur vs. Granular Sulfur:

- Physical Form:

- Lump Sulfur: Naturally occurring, solid chunks or pieces of sulfur, typically larger.

- Granular Sulfur: Sulfur particles are processed into small granules, uniform in size and shape.

- Application Method:

- Lump Sulfur: Often requires grinding or crushing before application to soil or incorporation into formulations.

- Granular Sulfur: Ready-to-use and can be applied directly to soil or blended into fertilizers for uniform distribution.

- Rate of Reaction:

- Lump Sulfur: Reacts relatively slowly with soil to lower pH and release sulfur, providing long-lasting benefits.

- Granular Sulfur: faster acting due to increased surface area, leading to quicker availability of sulfur for plant uptake.

- Suitability for Soil Types:

- Lump Sulfur: Effective in a wide range of soil types but may require more time to break down and release sulfur in heavy or compacted soils.

- Granular Sulfur: Suitable for various soil types, including sandy and loamy soils, with faster dissolution and sulfur release.

- Cost and Handling:

- Lump Sulfur: May be more cost-effective in terms of sulfur content per unit weight, but handling and application can be more labour-intensive.

- Granular Sulfur: Convenient to handle and apply, with uniform particle size contributing to ease of spreading, albeit potentially at a higher cost.

Understanding these differences between Lump Sulfur vs. Granular Sulfur allows farmers and industrial users to select the most appropriate sulfur form based on their specific needs, soil conditions, and crop requirements.

Both Lump Sulfur vs. Granular Sulfur offer valuable sulfur supplementation for optimal plant growth and soil fertility, with their distinct characteristics catering to diverse applications in agriculture and industry.

Lump sulfur versus granular sulfur

Lump Sulfur vs. Granular Sulfur is one of the great elements on Earth. It is widely used in industry for sulfuric acid production, agriculture, medicine, food, paper, and rubber industries.

It was once extracted from volcanic zones on the Earth’s surface or by drilling using hot air steam. However, more recently it has also been obtained from petroleum refining.

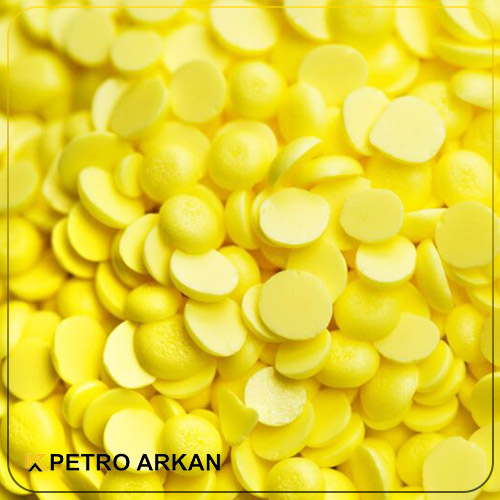

Sulfur Granules

Sulfur granules from actinomycosis and actinomycosis were examined histologically and ultrastructural. Lump Sulfur vs. Granular Sulfur from actinomycosis were large and elliptical or horseshoe-shaped.

Numerous gram-positive filamentous or short rod-shaped hyphae were present beneath the club. Lump Sulfur vs. Granular Sulfur, the centre of the sulfur granule consists of a cluster of hyphae, surrounded by radially arranged lobes.

The club consisted of electron-dense granules with central degenerated hyphae. The quantity of these granules varied from small to large.

In terms of host response, neutrophil infiltration around the Lump Sulfur vs. Granular Sulfur particles occurred first. Then, epithelial cells proliferated and phagocytosed the hyphae.

Sulfur Lump

These materials are required in excess for various applications in many industries such as the chemical industry. We actively strive to provide our customers with the best quality Lump Sulfur vs. Granular Sulfur.

Comparison of lump and granular sulfur

Lump Sulfur vs. Granular Sulfur, characterized by its large solid chunks or pieces, stands in contrast to granular sulfur, which comprises small, uniform particles or pellets.

In terms of handling, lump sulfur poses challenges due to its propensity for dust and breakage during transportation, whereas granular sulfur offers greater ease of handling owing to its reduced likelihood of dust formation and breakage.

Lump Sulfur vs. Granular Sulfur, lump sulfur tends to have a slower reaction rate owing to its reduced surface area, whereas granular sulfur demonstrates a faster reaction rate, facilitating quicker dissolution.

While lump sulfur is generally more cost-effective due to fewer processing requirements, granular sulfur may incur slightly higher costs due to additional processing for granulation.

Storage requirements also differ, with lump sulfur necessitating ample space due to its bulkiness, while granular sulfur demands less storage space owing to its smaller particle size.

Moreover, transportability favours granular sulfur for long-distance transportation due to its compactness and reduced susceptibility to breakage, contrasting with lump sulfur’s inefficiency in this regard. The chart below shows a comparison of Lump Sulfur vs. Granular Sulfur:

| Feature | Lump Sulfur | Granular Sulfur |

| Physical Form | Large solid chunks or pieces | Small, uniform particles or pellets |

| Handling | Prone to dust and breakage during transportation and handling | Less prone to dust and breakage, easier to handle |

| Application | Often used in industrial processes, such as refining and chemical manufacturing. | Widely used in agricultural applications, such as soil amendment for crop production. |

| Surface Area | Typically has lower surface area due to larger particle size | Higher surface area due to smaller particle size |

| Reaction Rate | Slower reaction rate due to lower surface area | Faster reaction rate due to higher surface area, leading to quicker dissolution |

Buying Lump Sulfur?

Are you in the market for sulfur to fuel your industrial processes? Look no further than our premium quality lump sulfur! With its large solid chunks and pieces, our lump sulfur offers unmatched reliability and performance in a variety of applications.

Say goodbye to dust and breakage woes during transportation and handling – our Lump Sulfur vs. Granular Sulfur is engineered for maximum durability and ease of use. Whether you’re in refining, chemical manufacturing, or other industrial sectors, our lump sulfur delivers exceptional results every time.

Petro Arkan, a leading name in the energy sector, stands as a beacon of innovation and excellence. With a commitment to Lump Sulfur vs. Granular Sulfur and cutting-edge technology, Petro Arkan continuously strives to push the boundaries of what’s possible in the oil and gas industry.

Summation

The distinction between Lump Sulfur vs. Granular Sulfur is paramount for both agricultural and industrial users. Lump sulfur typically exists as solid chunks, whereas granular sulfur is processed into uniform particles, offering differences in application methods and reaction rates.

We have great features for both Lump Sulfur vs. Granular Sulfur. While lump sulfur necessitates grinding before soil application, granular sulfur can be directly applied, showcasing faster reaction rates due to increased surface area.

FAQ Questions

- What are the main differences between lump sulfur and granular sulfur?

Lump sulfur is larger chunks; granular sulfur is small particles. Lump sulfur needs grinding; granular sulfur is ready to use. Granular sulfur reacts faster.

- Which industries commonly use lump sulfur and granular sulfur?

Lump sulfur – refining, chemical manufacturing. Granular sulfur – agriculture.

- What are the advantages and disadvantages of lump sulfur versus granular sulfur?

Lump sulfur is cheaper but requires grinding. Granular sulfur is easier to handle, and faster, but may cost more.

Other posts:

Pastille Sulfur vs. Granular Sulfur – 7 Differences between them

No comment